Discharge Drums KTR.

Sophisticated, tailor-made efficiency.

6.000 – 12.000 L/Min

16.000 – 31.000 liters

up to 200 cbm per hour

6.000 – 12.000 L/Min

16.000 – 31.000 liters

up to 200 cbm per hour

True revolutions begin in practice. KUMM Technik combines experience, craftsmanship and technology for high-quality products.

Tailored to your needs.

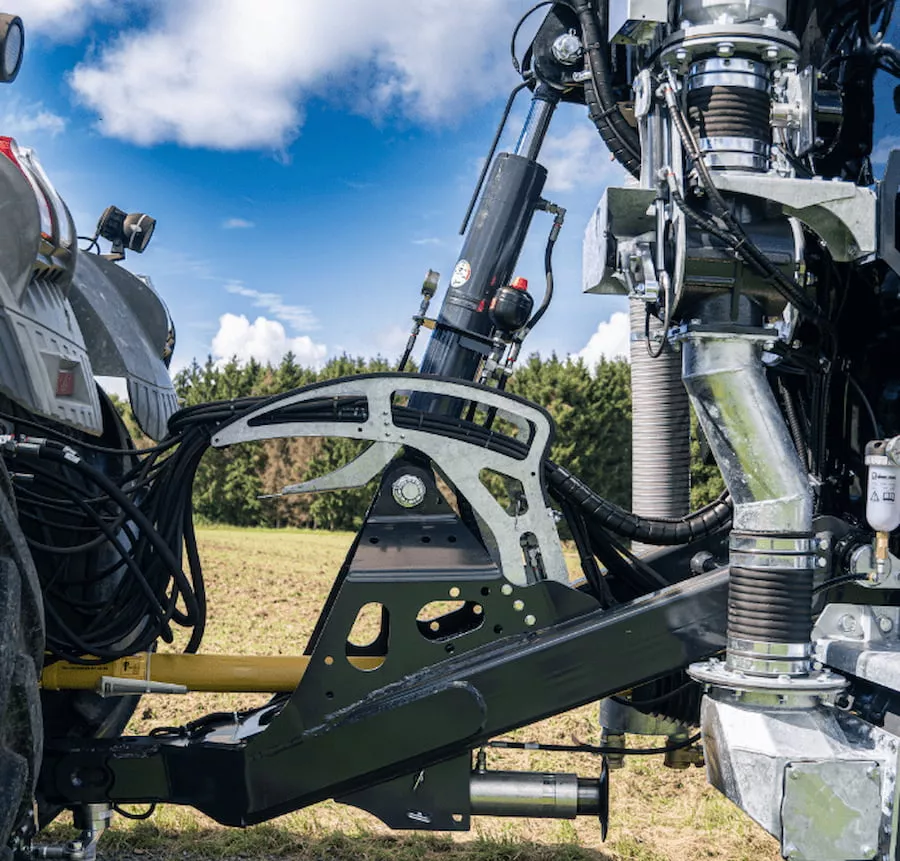

Versatile suspension options for your KTR

Let us advise you.

Thanks to the modular design, our KTRs are manufactured according to your requirements. We would like to get to know you personally and offer you the best possible advice. Give us a call or use our contact form for a consultation.

- PARTS & SERVICE

service@kumm-technik.de - DISTRIBUTION

vertrieb@kumm-technik.de

KTR TITAN – For the highest demands and the toughest conditions.

Our in-house production combines years of experience and craftsmanship with state-of-the-art technology to create an unmistakable product. High quality and the demand for durability and functionality ensure innovative slurry technology at KUMM Technik.

Craftsmanship meets technology: precision in every product.

Pumping technology

Duo pump system consisting of a high-performance centrifugal pump with up to 18,000 l/min for spreading and suction and a hydraulically driven 6,000 liter/min rotary lobe pump.

Chassis

Hydraulic tandem running gear with BPW AGRO turn axles and 900/60R38 or R42 tires including tire pressure regulation system. Rear axle is electronically forced steered by 17 degrees. Additional wheel drive on the first axle with up to 160 hp drive power.

Crane arm

10 inch pump tower for open slurry tanks or lagoons. Includes high-performance centrifugal pump with 15,000 l/min delivery capacity integrated in the crane arm. With mountable adapter also for suction at feeders as well as usable for agitating substrates. Extra large industrial ring gear with planetary drive and overload protection. Telescoping function up to 3,000 mm. Proportional control via joystick, automatic parking function.

Pumping technology

Chassis

Crane arm

Duo pump system consisting of a high-performance centrifugal pump with up to 18,000 l/min for spreading and suction and a hydraulically driven 6,000 liter/min rotary lobe pump.

Hydraulic tandem running gear with BPW AGRO turn axles and 900/60R38 or R42 tires including tire pressure regulation system. Rear axle is electronically forced steered by 17 degrees. Additional wheel drive on the first axle with up to 160 hp drive power.

10 inch pump tower for open slurry tanks or lagoons. Includes high-performance centrifugal pump with 15,000 l/min delivery capacity integrated in the crane arm. With mountable adapter also for suction at feeders as well as usable for agitating substrates. Extra large industrial ring gear with planetary drive and overload protection. Telescoping function up to 3,000 mm. Proportional control via joystick, automatic parking function.

KTR. Titan

Performance, efficiency and sophisticated design.

Highest quality from our own production.

Robust and efficient machines for contractors.

Get in touch with us.

Please use our contact form or simply give us a call.

Frequent asked questions.

A slurry tanker, often referred to as a slurry barrel or manure barrel, is designed for slurry transport. The KTR spreading barrel from KUMM Technik goes a step further by not only facilitating transport but also enabling precise slurry and digestate spreading with advanced technology like centrifugal pumps or rotary lobe pumps, making it an indispensable agricultural implement.

Yes, the KTR, colloquially known as a “slurry bomber,” is particularly suited for the efficient spreading of slurry over large areas. With its high pumping performance and large volume, it supports farmers in quickly and effectively spreading slurry.

Absolutely, the KTR serves as a special solution for direct field slurry transport, eliminating the need for an additional truck. This is made possible by its high capacity and the ability to directly connect to slurry pumps for hose spreading.

Tandem and tridem slurry tankers like the KTR offer improved stability and weight distribution, which is especially beneficial on uneven terrain or with heavy loads. These configurations allow for more efficient use and increase safety during slurry transport and application.

The KTR incorporates the latest spreading technology, including slurry distributors and special pumps, to ensure even and precise distribution of slurry. The availability of slurry tankers with centrifugal pumps or rotary lobe pumps and optional crane arms enhances flexibility and efficiency in slurry spreading.

KUMM Technik offers a wide range of options for slurry spreading, from single-axle slurry tankers for smaller farms to two-axle and three-axle slurry tankers for larger agricultural enterprises. Each device is designed to maximize the efficiency and effectiveness of slurry application.

Yes, there is an option to purchase a used KTR slurry tanker. KUMM Technik occasionally also offers refurbished models, providing a cost-effective alternative for farms that do not want to compromise on “Made in Germany” quality.

Slurry spreading with the KTR offers numerous benefits, including precise nutrient distribution, minimized soil compaction, and improved work speed. The combination of high pumping performance and specialized spreading technology makes the KTR an indispensable tool for efficient slurry management.

The modular pump tanker from KUMM Technik: Maximum performance, efficiency and impact. Unique for your business.